Four-stroke engines are IC Engines that take 4 strokes to complete one cycle of power generation. These type of engines are the primary choice engines in vehicles and equipments nowadays. In this article, we will discuss the working of a four-stroke engine in detail. We will also discuss the difference between four-stroke engines and two-stroke engines.

First, let’s learn a few facts about IC engines.

IC engines

- IC engines convert the chemical energy of a fuel into thermal energy which is converted into mechanical work using a piston, connecting rod, and crankshaft.

- In Internal Combustion engines, the combustion of fuel takes place in a combustion chamber located inside the Engine. Unlike External combustion engines in which the combustion chamber is located outside the engine body.

- IC engines are more thermally efficient and produce more power than EC engines in general.

Prerequisite knowledge

Intake and exhaust valve

The Air-fuel mixture moves into the combustion chamber from the intake valve. The exhaust valve is used to expel the exhaust gases from the combustion chamber.

Top Dead Centre (TDC) and Bottom Dead Centre (BDC)

The top dead center is the point when the piston is farthest away from the axis of the crankshaft. The bottom dead center is the point when the piston is nearest to the axis of the crankshaft.

What are the 4 strokes in a 4-stroke engine?

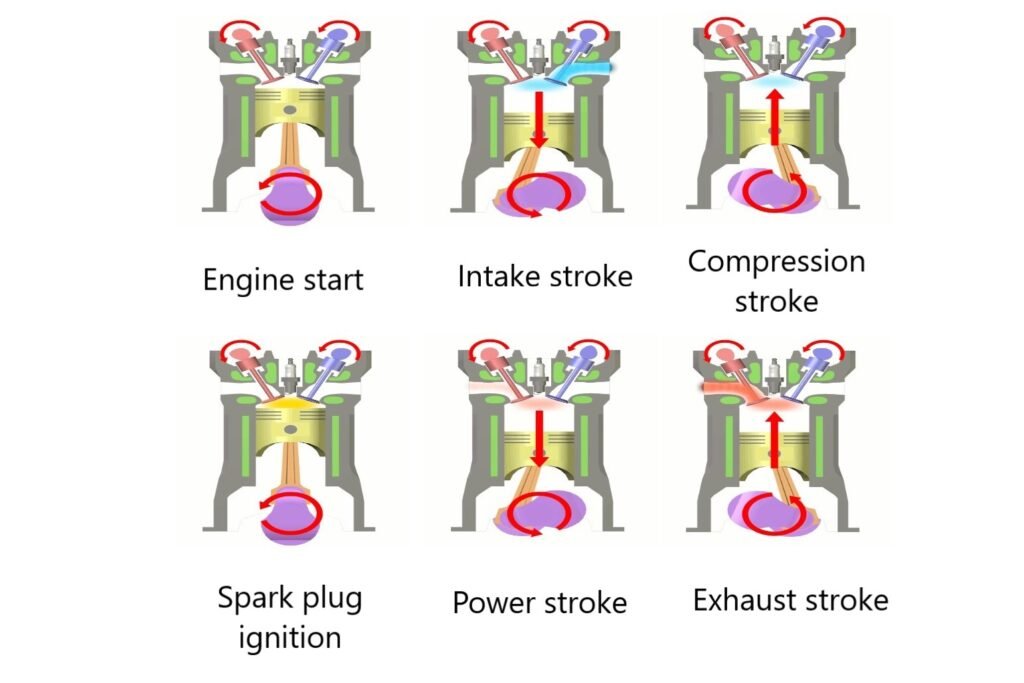

The four strokes in a 4-stroke engine are- Intake stroke, compression stroke, power stroke, and exhaust stroke. Let’s discuss the working of a four-stroke engine.

Note: The four strokes are explained for a spark-ignition engine (petrol engine).

Intake stroke

During the intake stroke, the piston moves downwards from TDC to BDC. As the piston moves down a vacuum is formed which forces the air-fuel mixture to move in the combustion chamber from the intake valve.

Compression stroke

During the compression stroke, the piston moves up from BDC to TDC and compresses the air-fuel mixture. The valves remain closed during this stroke.

Power stroke

The compressed air-fuel mixture is then ignited by the spark plug which forces the piston to move down and generate a power stroke. The valves remain closed during the power stroke.

Exhaust stroke

After the power stroke, the piston once again moves from BDC to TDC. This time the exhaust valve opens which expels the exhaust gases and makes the chamber ready to take the fresh air-fuel mixture.

These are the four strokes of a spark-ignition 4-stroke engine (petrol engine). The working is a bit different for compression ignition (diesel) 4-stroke engines.

In compression ignition engines, air moves in from the intake valve, unlike the air-fuel mixture in the case of a spark-ignition engine. After the compression stroke, fuel is sprayed by the fuel injector on the hot compressed air which burns the fuel and produces a power stroke.

Some key differences between 4-stroke and 2-stroke engines

| Four-stroke engine | Two-stroke Engine |

| The thermal efficiency is high. | The thermal efficiency is low. |

| There is one power stroke per two revolutions of the crankshaft. | There is one power stroke per single revolution of the crankshaft. |

| The power generated is lower as compared to a two-stroke engine. | The power generated is high. |

| Smooth functioning. | Requires more care and lubrication as compared to a four-stroke engine. |

| Less noisy. | More noisy. |

| Uses valves. | Uses ports. |

| Generates more torque at lower rpm. | Generates more torque at high rpm. |

Read more

What are two-stroke engines? | Two-stoke engine vs four-stroke engine