Two stroke engines are IC engines that take two strokes of the piston to complete one cycle of power generation. A few decades ago, the majority of vehicles and equipment had 2 stroke engines. Now, their place is taken by 4-stroke engines. 4-stroke engines have become popular because they have lower emissions and they provide better fuel economy. This article explains the working of two stroke engines and also lists the differences between two stroke and four stroke engines.

Prerequisite knowledge

Top dead center and bottom dead center

The top dead center is the point when the piston is farthest away from the axis of the crankshaft. The bottom dead center is the point when the piston is nearest to the axis of the crankshaft.

Crankcase

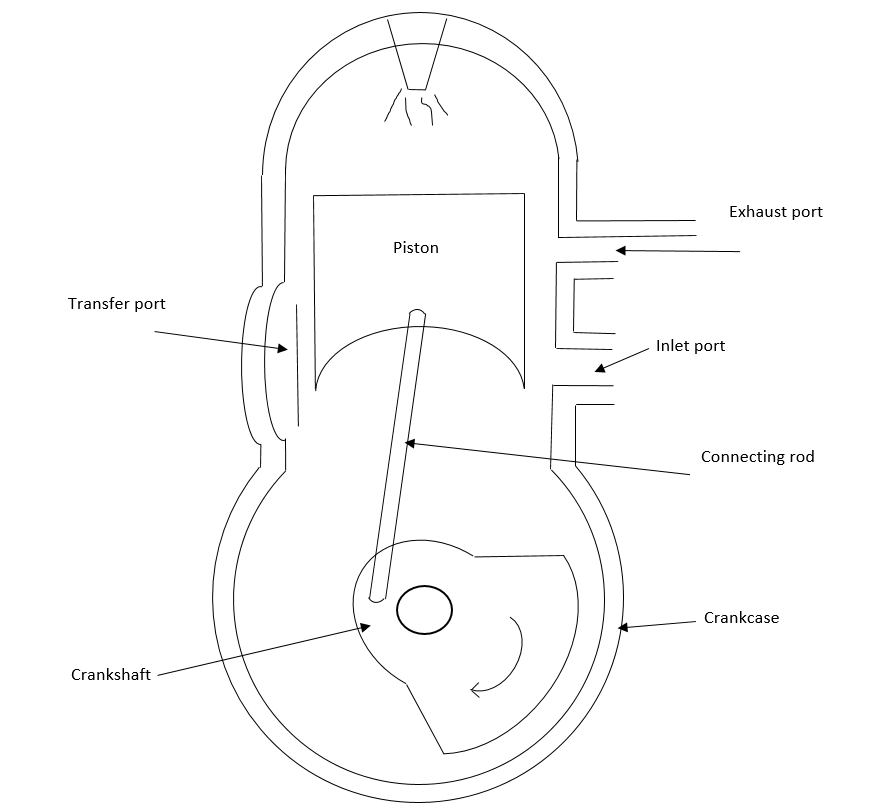

The crankshaft is enclosed within the Crankcase. In two-stroke engine, the crankcase also stores the air-fuel mixture.

Transfer port

It is used to transfer the air-fuel mixture from the crankcase to the combustion chamber.

Inlet or intake port

The air-fuel mixture enters through the intake port.

Exhaust port

The exhaust gases leave the combustion chamber through the exhaust port.

Carburetor

The carburetor mixes the air and fuel in the right amount for combustion.

Working of two stroke engines

Start

When the piston moves down the air-fuel mixture already in the crankcase is forced through the transfer port above the piston in the combustion chamber.

Compression stroke

When the piston starts to go up, more air-fuel mixture enters through the inlet port because of a vacuum formed in the crankcase. As the piston rises even more the transfer port is closed and the air-fuel mixture above the piston is compressed. A spark plug then ignites the compressed air-fuel mixture.

Power stroke

Because of ignition, the temperature and pressure inside the combustion chamber increase which forces the piston downwards. As the piston moves down an exhaust port is exposed through which exhaust gases move out.

As the piston moves further down the transfer port is opened. The downward-moving cylinder increases the pressure of air-fuel mixture in the crankcase. The air-fuel mixture once again moves from the crankcase to the combustion chamber through transfer ports. The cycle goes on like this.

For diesel engines

The above working is explained for 2 stroke petrol engines. For 2 stroke diesel engines, the air is supplied instead of the air-fuel mixture from the intake port. When the air is compressed in the combustion chamber the fuel is injected through a fuel injector which causes the power stroke.

Difference between 2 stroke and 4 stroke engine

| Two-stroke engine | Four-stroke engine |

|---|---|

| The power generated is high. | The power generated is low. |

| The thermal efficiency is low. | High thermal efficiency |

| Requires more care and maintenance. | Requires relatively less care. |

| The noise levels are high. | The noise levels are low. |

| Ports are used for intake and exhaust. | Valves are used for intake and exhaust. |

| There is one power stroke per single revolution of the crankshaft. | There is one power stroke per two revolutions of the crankshaft. |

| Higher torque is generated at higher rpm. | Higher torques can be achieved at low rpm. |

Read more